VisualGenius.AI

01 - AI Visual Inspections – Automated & Enhanced

Our intelligent platform customizes visual analysis based on user data and preferences, delivering personalized insights and re commendations. By understanding specific needs, the system enhances decision-making and efficiency, offering a bespoke experience in visual data interpretation.

Our platform’s advanced emotion recognition capabilities detect and analyze emotional cues from visual inputs. This allows the system to respond empathetically, creating deeper connections and providing support tailored to the user’s emotional state.

03 - Common Industry Challenges

04 - Applications Of VisualGenius.AI

By using advanced infrared cameras, our AI model can detect even the most minute anomalies, including casting defects and cracks, within just 100ms.

Our solution not only detects defects but also identifies the root causes of failures, enabling continuous process improvement.

MisticusMind ensures that every product meets its assured quality standards, reducing product returns and enhancing customer satisfaction.

We aim to shift the defect detection process earlier in the assembly line, allowing for the rejection of flawed products before they reach the end of the production cycle.

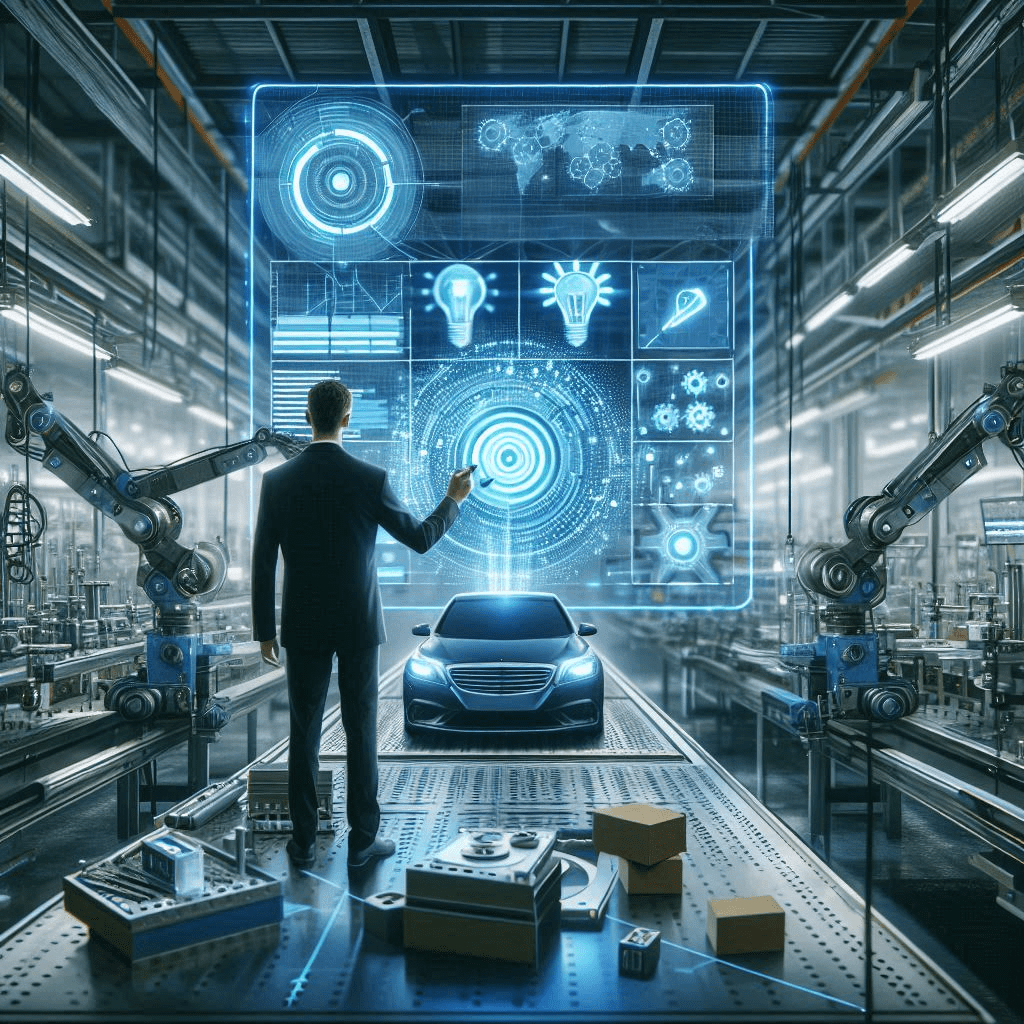

05 - Use Case

Seamless Product Flaw Detection with VisualGenius.ai

Industry: Automotive Manufacturing and Assembly Line Production

Challenge: Detecting product flaws efficiently in high-speed assembly lines.

Use Case Description:

MM provided a cutting-edge visual analysis solution for leading assembly line manufacturers and a large automotive company. With VisualGenius.ai, they can now seamlessly detect product flaws in real-time, significantly reducing inspection times and improving overall product quality.

Key Benefits:

- Increased Accuracy: Enhanced flaw detection with advanced AI algorithms.

- Efficiency Boost: Faster identification of defects, leading to quicker resolution.

- Scalability: Effective across various production lines with high volumes.

- Quality Improvement: Consistent product quality through real-time monitoring.